Humanity produces over 430 million tonnes of plastic a year globally, two-thirds of which are short-lived products that soon become waste. Abandoned, lost, and discarded fishing gear, known as “ghost gear”, is a critical yet often overlooked contributor to oceanic plastic pollution. It’s estimated to account for 20-30% of sea-based plastic litter.*

ReTraze collaborates with small businesses, fishermen, and NGOs to collect discarded fishing nets and transform them into 100% recycled PE.

Thanks to the collaboration with ReTraze, with the 2024 collection we have introduced our new visors made through the upcycling and recycling of discarded fishing nets and plastic bottles

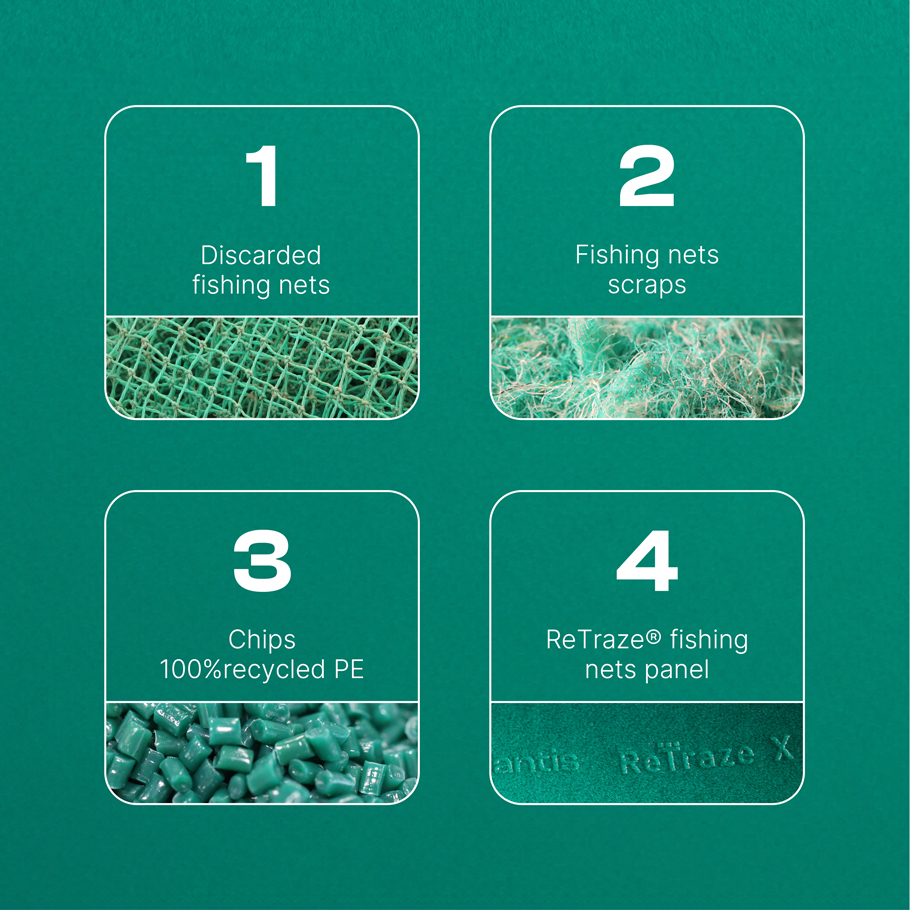

Since 2016, ReTraze has been actively involved in collecting these abandoned fishing nets. Through years of meticulous research and continuous improvements, they have established a vertical supply chain that effectively converts discarded fishing nets into 100% recycled PE ReTraze fishing net panels.

The recycling process employed by ReTraze involves physical methods, including sorting, cutting, washing, melting, chipping, extrusion, and precision cutting. Through their efforts, they not only reduce waste, but also create a product that stands testament to the potential of responsible recycling.

From 2024 productions, we proudly introduced recycled visors on all Atlantis collection’s items.

*Source: Turning off the Tap: How the world can end plastic pollution and create a circular economy – Authors: UNEP