What is it?

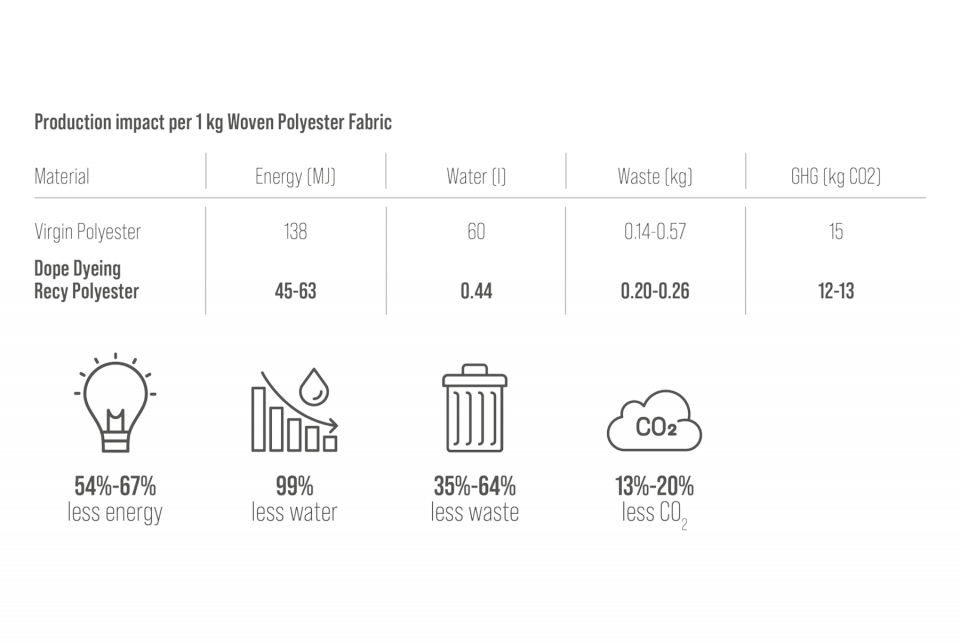

Our goal was to find a way to reduce the amount of water used in the dyeing process. The conventional dyeing process uses hot water and chemicals to make the color adhere to the synthetic fiber, consuming water, energy and emitting CO2.

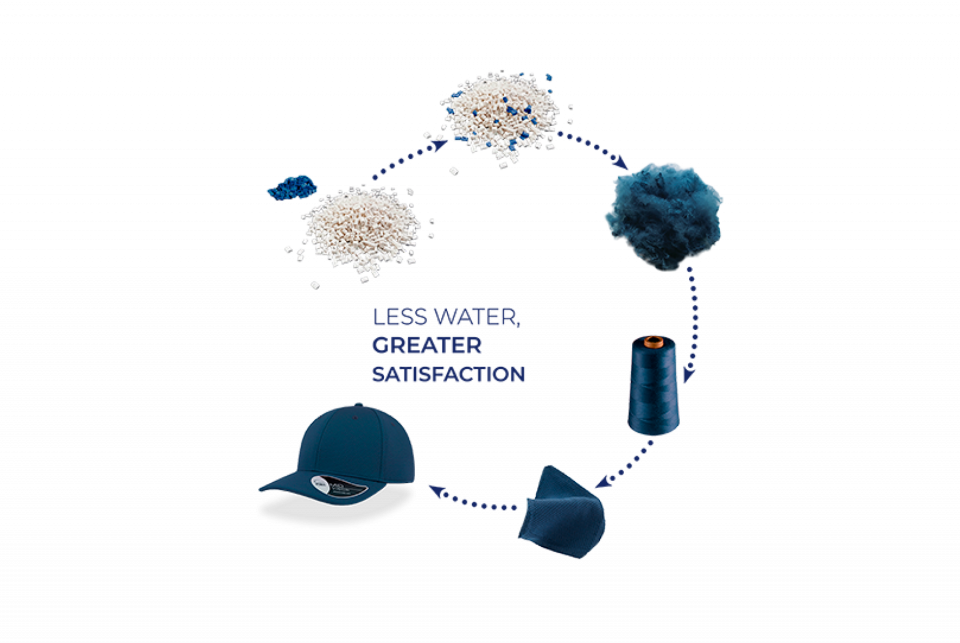

Dope dyeing, on the other hand, is a departure from traditional wet processing because of its reduced environmental impact. Typical of recycled polyester, it involves adding color pigments “upstream,” directly into the molten plastic solution before the fiber is made. Unlike traditional processes where yarns are made and then dyed, dope dyeing traps the pigments in the recycled plastic after it cools to a solid form and becomes part of the new, stronger yarn. With this approach, dyeing can be done by hot transfer without immersion in water.

We partner with ReTraze Aqua-®, a solution-dyed recycled polyester yarn that saves energy, water and emissions in the process. Their plastic bottle source is entirely collected within 20km of the coast and they continue to expand the collection area and tracking system. We’re constantly trying to improve our water savings and are looking for new and more efficient dyeing technologies to adopt as they become available.